Aviation AeroSpace

Quality Systems provides effective cleaning solutions for the Aviation and AeroSpace industries.

System Overview

System Overview

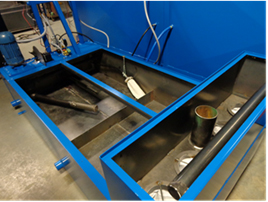

The Sharpertek MFST Cleaning machine is a drop-loading, single tank, industrial parts washer designed to a standard basket of parts at a time. ( Special sized baskets can be utilized.) It is ideal for washing a wide variety of parts such as Aerospace, Bearing, Screw Machined, Machined Casting, and other Precision Components in a lean, cellular operation. The heat, ultrasonic action, and chemistry effectively remove oils, soils, dirt, chips and other by-products associated with manufacturing from ID and OD areas.

Process Description

At a cycle rate of up to 2 baskets per hour, the production rate is up to 16 cubic feet of parts per hour. Cycle times are variable and dependent upon soils and parts. Actual time cycles will be confirmed when part testing is conducted .

|

Typical Sequence of Operation |

||

|

Process |

Description |

Duration |

|

Load |

Operator easily submerges baskets into machine, locks baskets, closes lid, presses Cycle Start Button |

5 sec |

|

Wash |

Wash pump rapidly fills process chamber, high volume ultrasonic cleaning begins |

12 m |

|

Drain |

Cleaning chemical is drained from processing tank |

3 m |

|

Rinse + N2 Blow-Off |

Clean water fills chamber to thoroughly rinse parts |

8 m |

|

Drain |

Water is drained from processing tank |

3 m |

|

Dry |

1600-cfm recirculation hot air dryer directs heated air at high velocity through multiple high-volume slots |

8 m |

|

Unload |

Operator opens lid, lifts baskets out of system |

5 sec |

|

|

Total seconds for complete cycle (without optional ultrasonic wash or rinse) |

40 m+ |

Concept of Operation

The MFST can process up to 5 baskets an hour.

A key feature is the system’s ability to keep the baskets submerged while simultaneously cleaning with heated solution and ultrasonics. This results in the best possible cleaning of complex-shaped parts by penetrating blind holes and cavities. The delivery of filtered Solution fully purges the cleaning chamber more than twice per minute, flushing soils and chips from the parts and process chamber, allowing even the most complex parts with blind holes to be effectively cleaned.

Years of innovation and development have resulted in proven, simple, and rugged design and construction elements that provide reliable operation.

Filtration

The solution is continually filtered through out the cleaning process. The entire volume of the cleaning chamber is turned over more than twice a minute. This fast recirculating turnover rate flushes away chips, soils and oils, always keeping fresh, clean solution in contact with the parts.

Filtered Rinse Water Discharge

Discharge solution is filtered during discharge process. Carbon filters are used to remove chemicals and oil that is dispersed in the solution.

Chip Removal

The cleaning chamber bottom is pitched from three sides for 100% quick drainage and chip removal. Chip strainer baskets are included for the tanks. All returning solution is filtered through these baskets to keep the storage tanks chip-free. Solution tanks do not have to be emptied to clean the baskets. To empty the chip baskets, the access door is opened, and the baskets are taken out.

Oil Removal -Optional

An optional belt-type oil skimmer or recirculation oil coalesce can be added to the wash tank for oil removal.

Recirculation Air Drying

The MFST uses a fast and efficient drying system, resulting in faster cleaning cycles than competitive machines. The dryer incorporates Sharpertek’s high volume and high velocity convection dryer which recirculates the air rather than discharging it into plant atmosphere. This system recirculates five times the air of competing systems, discharging the air flow through multiple slots aimed directly at into the tank. Over 95 percent of the air is re-circulated in the Sharpertek dryer, typically drying parts twice as fast while using lower air temperatures and half the energy of other systems.

Ergonomically Designed

Ergonomically designed lid helps operators work efficiently and stress free. Operator places a parts basket into the washer, closes the lid, and presses a button. Parts are washed consistently according to the wash program. Operators are free to complete other work while the MFST cleans the parts. Removing the basket is just as simple. The basket merely lifts out. Easy loading and unloading speeds cleaning and reduces operator time

Custom Built Washer: Designed to remove quench oil from jet engine thrusters – Power rollers move from staging through the wash chamber 8’9” Tall, 9’7” Deep, 20’ Long

Loading and unloading each are 3’5” Tall, 7’11” Deep, 21’7” Long capacity 5000 lbs.

Custom Drive on Wash Booth with Forklift Drive on Ramp

Built to clean Aircraft fuselage parts

Windows helps with visibility

High Pressure Gun with Hose Reel

Heated Tank Recirculates Water

Filtration removes particles

Oil Skimmer removes oil and grease

Custom sizes are available.